HyVe Documentation

Introduction

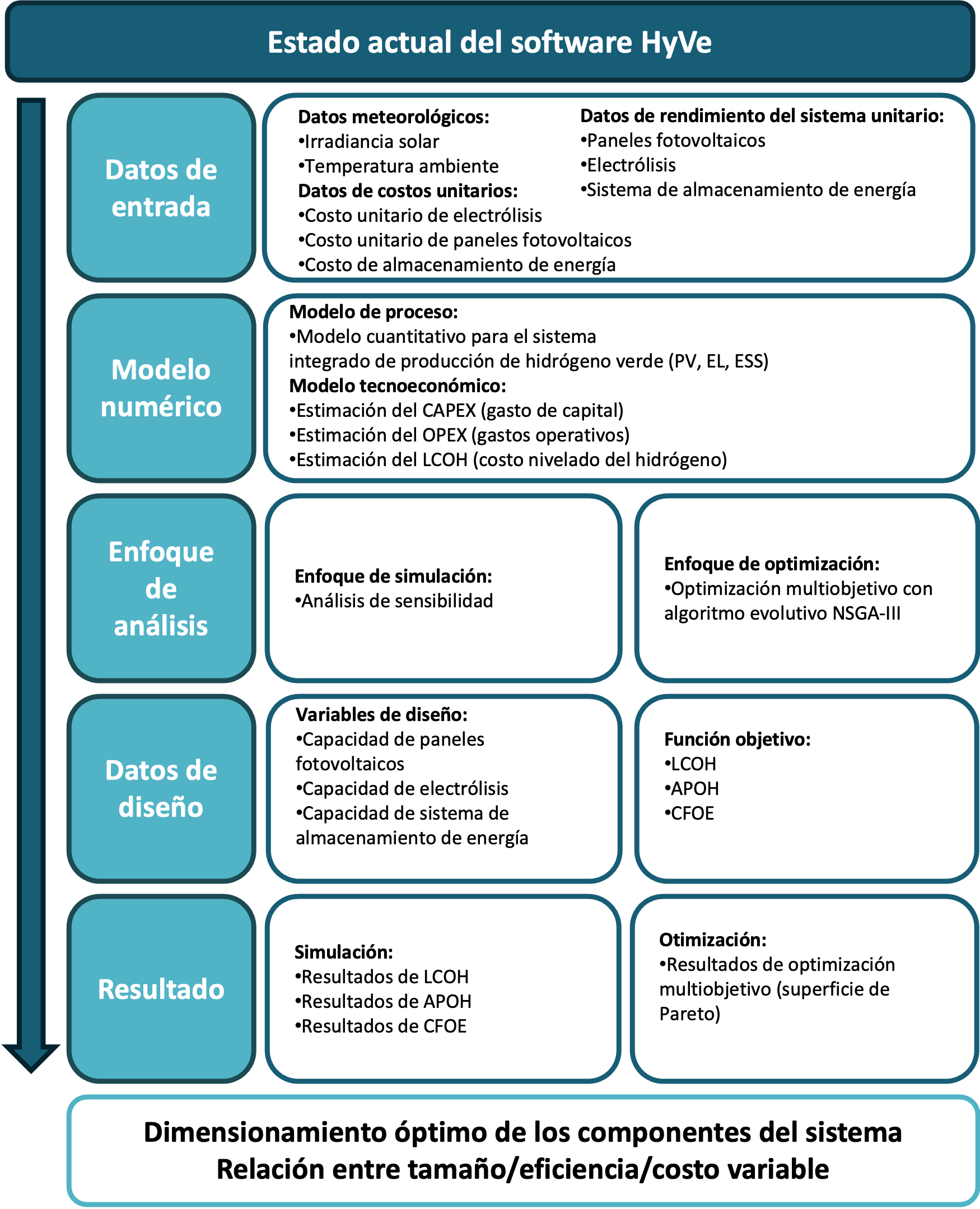

Welcome to the documentation page for HyVe, the advanced decision-making platform for green hydrogen (H2V) project development. HyVe leverages cutting-edge optimization techniques, artificial intelligence, and a robust risk management framework to help users design optimal configurations for H2V plants. This page provides all the necessary information to understand how HyVe works, its components, and the current development stage of the platform.

HyVe is currently at Technology Readiness Level (TRL) 3, which means it has passed the initial research and development stages and has been validated in a controlled environment through computational simulations and risk evaluations.

For further details on how the platform performed in a real-world case study, visit our Blog.

Key Features of HyVe

1. Comprehensive Plant Design Optimization

HyVe helps optimize the design of green hydrogen plants by finding the best combination of various components, such as:

- Photovoltaic (PV) panels

- Electrolyzers

- Energy storage systems (ESS)

- Hydrogen and ammonia storage

- Desalination systems

2. Advanced Multi-Objective Optimization

HyVe uses NSGA-III, an evolutionary optimization algorithm, to perform multi-objective optimization. This allows it to:

- Minimize the Levelized Cost of Hydrogen (LCOH)

- Maximize Net Present Value (NPV)

- Optimize energy efficiency and overall system performance

3. Risk Management and Sensitivity Analysis

HyVe integrates a Conditional Value at Risk (CVaR) approach for decision-making under uncertainty. This feature helps users assess how their projects will perform under variable market conditions, such as fluctuating energy prices or changing climate patterns. Sensitivity analysis allows the platform to measure the effect of uncertain parameters on key performance metrics.

4. Market Participation Module

Unlike other tools, HyVe incorporates strategies for market participation, helping users evaluate how their H2V plant interacts with electricity markets. This includes:

- Bilateral energy contracts

- Ancillary services

- Potential market incentives

Platform Overview

Input Data

HyVe requires the following types of input data:

- Meteorological Data: Irradiance, temperature, and other weather-related variables

- Component Performance Data: Efficiency of photovoltaic panels, electrolyzers, and storage systems

- Cost Data: CAPEX and OPEX for plant components, energy costs, etc.

Process Flow

- Data Input: Users input site-specific data, including climate conditions, performance metrics, and financial variables.

- Optimization: HyVe runs multi-objective optimization to find the best plant configuration.

- Simulation: The platform performs simulations to evaluate the economic and technical performance of the plant under various scenarios.

- Output: Users receive optimized designs along with a sensitivity analysis and risk evaluation, providing confidence in long-term decision-making.

Example of Input Variables:

- Solar Irradiance: 2500 kWh/m²/year (Antofagasta case)

- Electrolyzer Cost: 700 USD/kW

- PV Panel Cost: 550 USD/kWp

- Energy Storage Cost: 350 USD/kWh

Validation and Testing

The HyVe platform has been extensively tested in a controlled laboratory environment using simulation software. The tests demonstrate the viability of its optimization algorithms and models for green hydrogen plants. The case study of Antofagasta, Chile, offers real-world insights into HyVe’s performance.

Validation Metrics:

- LCOH Reduction: 2.50 USD/kg

- NPV Increase: 7% (up to 15 million USD over a 20-year horizon)

- Component Optimization: PV capacity of 100 MWp, Electrolyzer capacity of 40 MW, Energy storage capacity of 10 MWh

Modules in HyVe

1. Plant Dimensioning Module

This module helps determine the optimal size of various components, such as PV panels, electrolyzers, and energy storage systems, ensuring that the plant’s operational needs are met while minimizing costs.

2. Market Participation Module

This module evaluates the plant’s strategies for engaging with energy markets, considering elements such as contracts and service incentives.

3. Simulation and Performance Evaluation Module

This module runs simulations to assess the long-term performance of the plant in terms of LCOH, NPV, and other key financial and operational indicators.

Technology Readiness Level (TRL)

HyVe is at TRL 3, which indicates that:

- The fundamental concepts and principles have been established and tested in a controlled environment.

- A prototype has been developed using Python-based software, and its functionality has been validated through simulations.

- The platform is ready for more extensive field testing and further refinement before commercial deployment.

For further details on our research and development journey, you can visit the following pages:

Future Development Plans

HyVe will continue evolving toward TRL 6 by testing in real-world environments, improving its algorithms, and scaling up its capabilities to handle larger, more complex projects. We plan to collaborate with industry stakeholders to pilot the platform in actual green hydrogen projects across various regions.